Due to the characteristics of the lithium battery itself, it is necessary to add a battery protection board (PCM) or a battery management system (BMS). The use of batteries without a protection board or management system is prohibited, and there will be huge safety risks. Safety is always the first priority for battery systems.

If the battery is not well protected or managed, there may be a risk of short life, damage or explosion.

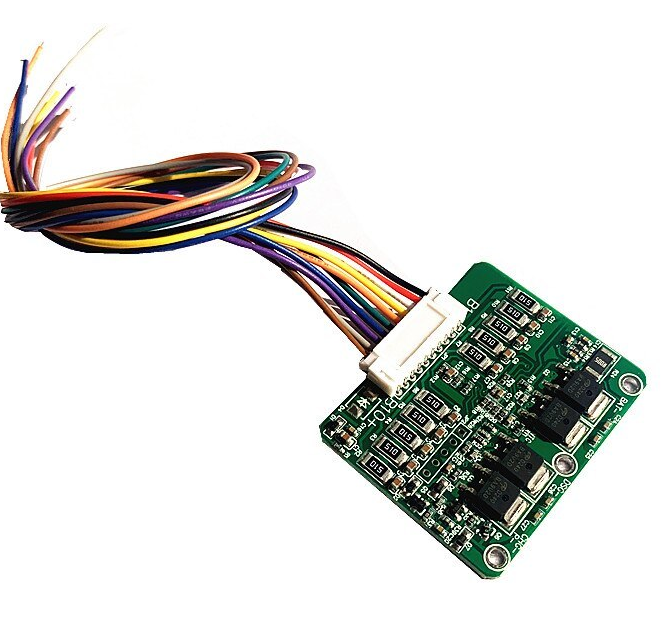

Battery protection boards (PCM: Power Circuit Module) are mainly used in consumer products such as mobile phones and notebooks.

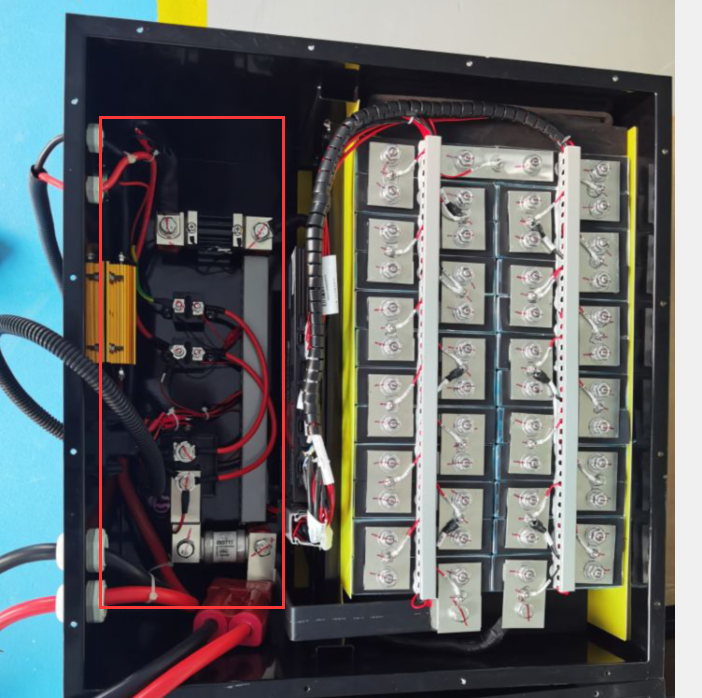

Battery Management System (BMS: Battery Management System) is mainly used in power batteries, such as electric vehicles, electric bicycles, energy storage and other large systems.

Battery protection (PCM) main functions, battery overcharge protection (OVP), over discharge protection (UVP), over temperature protection (OTP), over current protection (OCP), etc. Once an abnormal situation occurs, the system automatically shuts down to ensure system safety.

The battery protection system technology is very mature. There are many related board manufacturers, mainly in southern China. There are specialized IC manufacturers to provide specialized lithium battery protection chips. This one is relatively mature. There are many mature protection IC chips in China. come out.

In addition to the basic protection functions of the protection system, the main functions of the battery management system (BMS) include battery voltage, temperature and current measurement, energy balance, power (SOC) calculation and display, abnormal alarm, charge and discharge management, communication, etc. Some BMS systems also integrate heat management, battery heating, battery health (SOH) analysis, insulation resistance measurement, etc.

BMS function introduction and analysis:

- Battery protection is similar to PCM, overcharge, overdischarge, overtemperature, overcurrent, and short circuit protection. Like ordinary lithium manganese batteries and ternary lithium batteries, once the voltage of any battery exceeds 4.2V or the voltage of any battery is lower than 3.0V, the system will automatically cut off the charging or discharging circuit. If the battery temperature exceeds the battery operating temperature or the current is greater than the battery discharge current, the system will automatically cut off the current path to ensure the safety of the battery and the system.

- Energy balance, the entire battery pack, because many batteries are connected in series, after working for a certain period of time, due to the inconsistency of the battery cell itself, the inconsistency of the working temperature and other reasons, it will eventually show a big difference. The lifespan of the battery and the use of the system have a huge impact. Energy balance is to make up for the differences between individual battery cells to do some active or passive charge or discharge management to ensure the consistency of the battery and extend the life of the battery.

In the industry, there are generally two types of passive balancing and active balancing. Passive balancing is mainly to balance the power with more power through resistance consumption. Active balancing is mainly to transfer the power of the battery with more power to the less power through capacitor, inductor or transformer. The battery reaches equilibrium. See the table below for the comparison of passive and active balance.

Because the active balancing system is relatively complex and the cost is relatively high, the mainstream is still passive balancing.

| Comparison item | Passive balance | Active balance |

| Balance method | resistance consumption | inductance transfer etc |

| Balanced efficiency | Low | High |

| Program maturity | mature | relatively mature |

| System complexity | Low | High |

| System cost | Low | High |

- SOC calculation, battery power calculation is a very important part of BMS, and many systems need to know the remaining power more accurately. Due to the development of technology, many methods have been accumulated for SOC calculation. The remaining power can be judged according to the battery voltage if the accuracy is not required. The main accurate method is the current integration method (also called Ah method), Q = ∫i dt, and There are internal resistance method, neural network method, Kalman filter method and so on. The mainstream in the industry is still the current scoring method.

- For communication, different systems have different requirements for communication interfaces. The mainstream communication interfaces include SPI, I2C, CAN, RS485, etc. Among them, the automobile and energy storage systems are mainly CAN and RS485.

Due to insufficient competition in the BMS system and the complexity of the system, there are relatively few system vendors. The related chip vendors are mainly European and American manufacturers, and there are a few large domestic companies in the development.